Johns Manville Insulation and Cover Board

We'll design a solution to meet your covering and insulation criteria.

As for cover boards, Georgia-Pacific DensDeck with their Econic™ technology leads the way to enhancing and protecting any roofing system.

JM offers high-density polyiso, low-density polyiso, cement, and gypsum cover boards.

JM and Georgia-Pacific have solutions that can meet all types of design criteria: a system for high-impact zones, fire-retardant solutions that meet UL Class A requirements, products that do not support mold growth, acoustic design and more.

Insulation and Cover Board Product Guide

SeparatoR

SeparatoR

Meets the requirements of ASTM C 1289, Type II, Class 1, Grade 2

Closed Cell Polyisocyanurate Foam Core: Provides high R-value per inch, light weight, and flexibility in recover and metal retrofit applications.

Glass-Reinforced Facers: Provides rigidity and resistance to indentation and crushing for mechanically fastened single ply membrane systems.

High R-Value (2.8 R): 1/2" SeparatoR Board has more than two times the R-value of wood fiber or gypsum boards.

SeparatoR FR

Meets the requirements of ASTM C 1289, Type II, Class 2, Grade 3

UL Class A: When installed over a combustible wood deck and covered with a mechanically fastened or induction welded single ply membrane.

Closed Cell Polyisocyanurate Foam Core: Provides high R-value per inch, light weight, and flexibility.

Inorganic Coated Glass Facers: (With no cellulose) Provide improved resistance to mold growth as well as rigidity and resistance to indentation and crushing for mechanically fastened single ply membrane systems. The premium coated FR facer yields UL Class A combustible deck assembly rating without the need for a gypsum cover board or slip sheet.

High R-Value (2.9 R): Has more than two times the R-value of wood fiber or gypsum boards.

User Friendly: Allows easy and efficient scoring, cutting and snapping which permits fast, tight fabrication and all in a low dust environment.

Lightweight: Offers labor and installation efficiencies. This also means easy hoisting, staging and maneuvering around the roof.

ProtectoR HD

ProtectoR HD

Meets the requirements of ASTM C 1289, Type II, Class 4, Grade 1

High-Density Polyisocyanurate Foam Core: Closed cell polyisocyanurate foam technology provides additional insulation value (R-value of 2.5), with lightweight and low water absorption characteristics.

Inorganic Coated Glass Facers: (With no cellulose) Provide improved resistance to mold growth, as well as a smooth surface that performs well with self-adhering systems, and efficient adhesive application in adhered single ply systems.

Lightweight: Offers labor and installation efficiencies and allows more options for situations where the overall weight is a concern. This also means easy hoisting, staging and maneuvering around the roof.

High R-Value (2.5 R): Provides significantly more thermal insulation (R-value) than wood fiber or gypsum boards.

User Friendly: ProtectoR HD allows easy & efficient scoring, cutting and snapping which permits fast, tight fabrication and all in a low dust environment.

Resistance To Damage: High impact, flexural and compressive strength pro- vides a protective layer for insulation while working with the membrane above to ensure maximum performance and longevity.

Up to 50% Fewer Fasteners: Achieves FM 1-90 utilizing 8 fasteners per 4'x8'board with an adhered reinforced membrane and 11 fasteners per 4'x 8' board with an adhered non-reinforced membrane over a min. 22 ga steel deck or structural concrete deck.

JM DuraBoard

DuraBoard

Meets the requirements of ASTM C 728, Type 2

Polymerized Asphalt Emulsion Coating: Allows for direct application of SBS or APP membranes using torch application techniques, and does not require pre-heating like heavily coated boards. This allows for fuel savings and labor efficiency by eliminating fasteners with a mechanically fastened base sheet.

Expanded Perlite: Provides good dimensional stability, excellent insulation value with stable R-value and fire resistance.

Reinforcing Cellulosic Fibers: Consists of recycled newsprint to provide strength to the board as well as high recycled content. JM utilizes third party certification by UL environment to certify the recycled content and contributes to the LEED Materials and Resource (MR) credit 4.

High Density: Provides additional strength and durability.

DuraFoam

Meets the requirements of ASTM C 1289, Type III

Polymerized Asphalt Emulsion Coating: Allows for the direct application of SBS or APP membranes utilizing heat-weld application techniques.

Rigid Roof Insulation Board: Composed of a closed cell polyisocyanurate foam core bonded in the foaming process to 1/2" thick DuraBoard®, an expanded perlite mineral aggregate board, on one side, and a fiber glass reinforced facer on the other. It's light weight provides ease of handling.

High Thermal Efficiency: Utilizes an environmentally compliant blowing agent containing pentane hydrocarbon to enhance the thermal performance of the foam insulation.

ENRGY 3

ENRGY 3 - Flat and Tapered

Meets the following requirements:

- ENRGY 3 / Tapered ENRGY 3

- CAN/ULC S704, Type 2, Class 3 (140 kPa)

- ASTM C 1289, Type II, Class 1, Grade 2 ENRGY 3 25 PSI / Tapered ENRGY 3 25 PSI

- CAN/ULC S704, Type 3, Class 3 (170 kPa)

- ASTM C 1289, Type II, Class 1, Grade 3

Glass-Reinforced Facers: Provides rigidity and resistance to indentation and crushing, and are compatible with BUR, modified bitumen and single ply membrane systems.

Closed Cell Polyisocyanurate Foam Core: Provides high R-value per inch in built-up, modified bitumen, metal roof and single ply roof systems, and utilizes a zero ozone depletion blowing agent that provides high thermal insulation performance.

ENRGY 3 CGF - Flat and Tapered

Meets the following requirements:

- ENRGY 3 CGF / Tapered ENRGY 3 CGF

- CAN/ULC S704, Type 2, Class 3 (140 kPa)

- ASTM C 1289, Type II, Class 2, Grade 2

- ENRGY 3 25 PSI CGF / Tapered ENRGY 3 25 PSI CGF

- CAN/ULC S704, Type 3, Class 3 (170 kPa)

- ASTM C 1289, Type II, Class 2, Grade 3

Inorganic Coated Glass Facers: (With no cellulose) Provide improved resistance to mold growth, as well as a smooth surface that performs well with self-adhering systems, and efficient adhesive application in fully adhered single ply systems.

Closed Cell Polyisocyanurate Foam Core: Provides high R-value per inch in built-up, modified bitumen, metal roof and single ply roof systems, and utilizes an environmentally compliant blowing agent that provides high thermal insulation performance.

ENRGY 3 FR - Flat and Tapered

Meets Requirements:

- ASTM C 1289, Type II, Class 2 Grade 2 (20 psi)

- ENRGY 3 FR / Tapered ENRGY 3 FR

- Grade 3 (25 psi)

- ENRGY 3 25 PSI FR / Tapered ENRGY 3 25 PSI FR

Inorganic Coated Glass Facers: (With no cellulose) Provide improved resistance to mold growth as well as rigidity and resistance to indentation and crushing for mechanically fastened single ply membrane systems. The premium coated FR facer yields UL Class A combustible deck assembly rating without the need for a gypsum cover board or slipsheet.

Closed Cell Polyisocyanurate Foam Core: Provides high R-value per inch in built-up, modified bitumen, metal roof and single ply roof systems, and utilizes an environmentally compliant blowing agent that provides high thermal insulation performance.

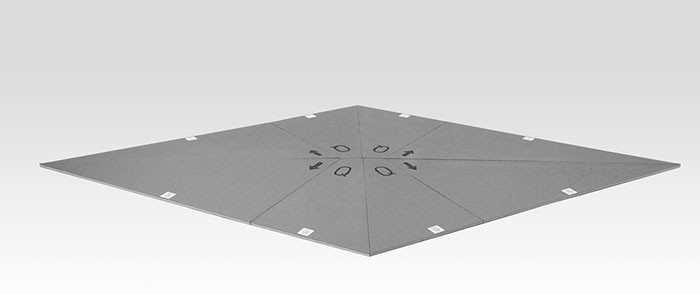

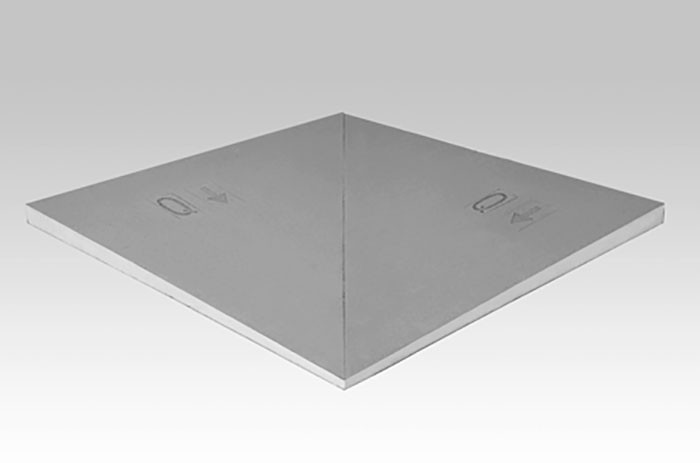

JM DiamondBack Pre-Cuts

DiamondBack Pre-Cut Crickets

Meets the requirements of ASTM C 1289, Type II, Class 1,

Grade 2 (20 psi)

- DiamondBack Pre-Cut Crickets Grade 3 (25 psi)

- DiamondBack 25 PSI Pre-Cut Crickets

Glass-Reinforced Facers: Provide rigidity and protection to the foam core and are compatible with BUR, modified bitumen and single ply membrane systems.

Closed Cell Polyisocyanurate Foam Core: Utilizes an environmentally compliant blowing agent that provides high thermal insulation performance.

Precise Factory Cuts: Custom designed to provide reduced job-site waste disposal, increased labor efficiency and smooth field transitions.

Diamondback Pre-Cut Miters

Meets the requirements of ASTM C 1289, Type II, Class 1,

Grade 2 (20 psi)

- DiamondBack Pre-Cut Miters Grade 3 (25 psi)

- DiamondBack 25 PSI Pre-Cut Miters

- Glass-Reinforced Facers: Provide rigidity and protection to the foam core and are compatible with BUR, modified bitumen and single ply membrane systems.

Closed Cell Polyisocyanurate Foam Core: Utilizes an environmentally compliant blowing agent that provides high thermal insulation performance.

Precise Factory Cuts: Custom designed to provide reduced job-site waste disposal, increased labor efficiency and smooth field transitions.

FESCO

FesCant Plus and Tapered FESCO Edge Strip

Expanded Perlite: Provides good dimensional stability and excellent insulation value with stable R-value. The high perlite content offers far greater fire resistance than conventional wood fiber materials.

Reinforcing Cellulosic Fibers: Consists of recycled newsprint to provide strength to the board as well as high recycled content. JM utilizes third party certification by UL® Environment to certify the recycled content and contributes to the LEED® Materials and Resource (MR) credit 4.

FesCant Plus Cant Strips: Manufactured from JM Cant Board, a high-density, laminated perlite board that provides excellent transition from the deck to the wall of the roof.

Tapered FESCO Edge Strips: Excellent for transitioning from membrane to nailer, or transitioning from Tapered FESCO®, Tapered ENRGY 3®, or Tapered Fesco Foam® panels to the roof level to help promote positive drainage.

FESCO Board

Meets the requirements of ASTM C 728, Type 1

TopLoc® Coating: Top surface is sealed with this special coating to reduce excessive asphalt absorption in hot-asphalt applied roofing systems.

Expanded Perlite: Provides good dimensional stability, excellent insulation value with stable R-value and fire resistance.

Low Thermal Insulation Board: Composed of expanded perlite, reinforcing cellulosic fibers and selected binders.

Reinforcing Cellulosic Fibers: Consists of recycled newsprint to provide strength to the board as well as high recycled content. JM utilizes third party certification by UL® Environment to certify the recycled content and contributes to the LEED Materials and Resource (MR) credit 4.

Hot Asphalt Friendly: Protective cover board or low thermal insulation board proven to reduce the tendency for blistering in hot asphalt applications.

Fesco Foam - Flat and Tapered

Meets the requirements of ASTM C 1289, Type III

Fesco Foam / Tapered Fesco Foam

TopLoc® Coating: Top surface is sealed with this special coating to reduce excessive asphalt absorption in hot-asphalt applied roofing systems.

Rigid Roof Insulation Board: Composed of a closed cell polyisocyanurate foam core bonded in the foaming process to RetroPlus Roof Board on one side and a glass-reinforced facer on the other. RetroPlus Roof Board is an expanded perlite mineral aggregate board.

High Thermal Efficiency: Utilizes an environmentally compliant blowing agent containing pentane hydrocarbon to enhance the thermal performance of the foam insulation.

FESCO HD

Meets the requirements of ASTM C 728, Type 2

TopLoc® Coating: Top surface is sealed with this special coating to reduce excessive asphalt absorption in hot-asphalt applied roofing systems.

Expanded Perlite: Provides good dimensional stability, excellent insulation value with stable R-value and superior fire resistance.

Reinforcing Cellulosic Fibers: Consists of recycled newsprint to provide strength to the board as well as high recycled content. JM utilizes third party certification by UL environment to certify the recycled content and contributes to the LEED Materials and Resource (MR) credit 4.

High Density:* Allows for installations directly over a wide flute or metal deck application for spans up to 2½" and resists damage from construction and maintenance.

Hot Asphalt Friendly: Can be used as a cover board in re-roofing and new construction, proven to reduce the tendency for blistering in hot asphalt applications.

*For direct to deck application, contact JM technical services for specific requirements and system compatibility

Tapered Fesco Board

Meets the requirements of ASTM C 728, Type 1

TopLoc® Coating: Top surface is sealed with this special coating to reduce excessive asphalt absorption in hot-asphalt applied roofing systems.

Expanded Perlite: Provides good dimensional stability, excellent insulation value with stable R-value and fire resistance.

Tapered Design: Factory cut taper, that is easy to install and cut, builds slope into an otherwise flat roofing system, allowing water to drain freely off the roof.

Reinforcing Cellulosic Fibers: Consists of recycled newsprint to provide strength to the board as well as high recycled content. JM utilizes third party certification by UL environment to certify the recycled content and contributes to the LEED Materials and Resource (MR) credit 4.

Hot Asphalt Friendly: Perlite board proven to reduce the tendency for blistering in hot asphalt applications.

Retro-Fit Board

Half-Inch Retro-Fit Board

Meets the requirements of ASTM C 728, Type 2

TopLoc® Coating: Top surface is sealed with this special coating to reduce excessive asphalt absorption in hot-asphalt applied roofing systems.

Expanded Perlite: Provides good dimensional stability, excellent insulation value with stable R-value and fire resistance.

Reinforcing Cellulosic Fibers: Consists of recycled newsprint to provide strength to the board as well as high recycled content. JM utilizes third party certification by UL environment to certify the recycled content and contributes to the LEED Materials and Resource (MR) credit 4.

Hot Asphalt Friendly: Utility board for use as a divorcing layer in re-roofing and in new construction as a top layer in multi-layer insulation systems proven to reduce the tendency for blistering in hot asphalt applications.

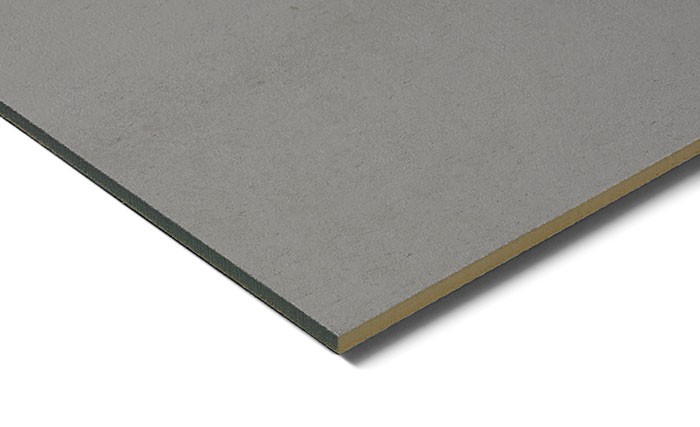

JM Invinsa

Invinsa

Meets the requirements of ASTM C 1289, Type II, Class 4, Grades 1, 2 and 3

High-Density Polyisocyanurate Foam Core: Closed cell polyisocyanurate foam technology provides additional insulation value, with lightweight and low water absorption characteristics.

Inorganic Coated Glass Facers: (With no cellulose) Provide improved resistance to mold growth, as well as a smooth surface that performs well with self-adhering systems, and efficient adhesive application in fully adhered single ply systems.

Lightweight: Offers labor and installation efficiencies and allows more options for situations where the overall weight is a concern. This also means easy hoisting, staging and maneuvering around the roof.

Flexibility: Means less breakage during handling, and in re-cover applications it allows Invinsa to accommodate minor irregularities in existing roofs.

User Friendly: Invinsa allows easy & efficient scoring, cutting and snapping which permits fast, tight fabrication and all in a low dust environment.

Resistance To Damage: High impact, flexural and compressive strength provides a protective layer for insulation while working with the membrane above to ensure maximum performance and longevity

Invinsa Foam

Meets the following requirements:

High-Density layer meets the requirements of ASTM C 1289,

Type II, Class 4, Grades 1, 2, & 3

Normal-Density layer meets the requirements of ASTM C 1289,

Type II, Class 2

Currently no ASTM designation for this composite.

High-Density Foam (Invinsa): Provides the highest compressive strength (150 psi nominal) polyisocyanurate board on the market today. Provides a protective layer for insulation while working with the membrane above to ensure maximum performance and longevity.

Normal-Density Foam (ENRGY 3 CGF): Closed cell polyisocyanurate foam manufactured inline to create a homogeneous board with Invinsa® and coated glass facers.

Inorganic Coated Glass Facers: (With no cellulose) Provide improved resistance to mold growth, as well as a smooth surface that performs well with self-adhering systems, and efficient adhesive application in fully adhered single ply systems.

Cost Savings: Installation labor savings by combining cover board and insulation into a single board. Eliminates adhesive cost to adhere cover board to insulation.

Invinsa FR

Meets the requirements of ASTM C 1289, Type II, Class 4, Grades 1, 2, and 3

High-Density Polyisocyanurate Foam Core: Closed cell polyisocyanurate foam technology provides additional insulation value, with lightweight and low water absorption characteristics.

Inorganic Coated Glass Facers: (With no cellulose) Provide improved reisistance to mold growth, as well as a smooth surface that performs well with self-adhering systems, and efficient adhesive application in fully adhered single ply systems.

Lightweight: Offers labor and installation efficiencies and allows more options for situations where the overall weight is a concern. This also means easy hoisting, staging and maneuvering around the roof.

Flexibility: Means less breakage during handling, and in re-roof applications it allows Invinsa to accommodate minor irregularities in existing roof decks.

User Friendly: Invinsa allows easy & efficient scoring, cutting and snapping which permits fast, tight fabrication and all in a low dust environment.

Resistance To Damage: High impact, flexural and compressive strength provides a protective layer for insulation while working with the membrane above to ensure maximum performance and longevity.

JM DensDeck

JM DensDeck Prime Roof Board

Meets the requirements of ASTM C 1177

Enhanced Face Mat: Coated fiberglass facer ideal for fully adhered systems provides a broader compatibility and higher performance with roofing adhesives.

Fire Performance: FM Class 1 for fire barrier requirements and UL Class A unlimited slope with excellent surface burning characteristics. 5/8" thickness meets the requirements of Type X per ASTM C 1177.

JM DensDeck Roof Board

Meets the requirements of ASTM C 1177

Fire Performance: FM Class 1 for fire barrier requirements and UL Class A unlimited slope with excellent surface burning characteristics. 5/8" thickness meets the requirements of Type X per ASTM C 1177.

Moisture and Mold Resistance: Scores a 10, the highest performance level for mold resistance, when tested in accordance with ASTM D 3273.

JM DEXcell

JM DEXcell Cement Roof Board

Meets the requirements of ASTM C 1325

Durability: Composed of a lightweight cementicious core to provide exceptional impact resistance.

Strength: Exceptionally high compressive strength improves overall roof system performance. Cement board is able to withstand prolonged exposure to moisture and is ideal for systems where wind uplift and puncture resistance are a concern.

Fire Performance: FM Class 1 for fire barrier requirements and UL Class A unlimited slope with excellent surface burning characteristics.

Moisture and Mold Resistance: Cement based core provides superior moisture, mold, and mildew resistance. Scores a maximum "10" for mold resistance when tested per ASTM D 3273.

JM DEXcell FA Glass-Mat Roof Board

Meets the requirements of ASTM C 1177

Handleability: Heavy duty coated fiberglass facer ideal for fully adhered systems improves handling and strength. Scores and snaps easily.

Strength: High compressive strength improves overall roof system performance. Ideal for systems where wind uplift and puncture resistance are a concern.

Fire Performance: FM Class 1 for fire barrier requirements and UL Class A unlimited slope with excellent surface burning characteristics. 5/8" thickness meets the requirements of Type X per ASTM C 1177.

Moisture and Mold Resistance: Enhanced mold resistant core and coated fiberglass facers provide mold and mildew resistance per ASTM-D 3273.

JM DEXcell Glass-Mat Roof Board

Meets the requirements of ASTM C 1177

Handleability: Coated fiberglass facer ideal for mechanically fastened systems improves handling and strength. Scores and snaps easily.

Fire Performance: FM Class 1 for fire barrier requirements and UL Class A unlimited slope with excellent surface burning characteristics. 5/8" thickness meets the requirements of Type X per ASTM C 1177.

Moisture and Mold Resistance: Enhanced mold resistant core and coated fiberglass facers provide mold and mildew resistance per ASTM-D 3273.

JM SECUROCK

JM SECUROCK Cement Roof Board

Meets the requirements of ASTM C 1325

Ideal for liquid applied membrane roof systems.

Strength: Engineered to provide superior wind-uplift performance for a wide variety of roof assemblies. The board is formed using an aggregated portland cement slurry with a polymer-coated, glass-fiber mesh completely encompassing edges and both surfaces, to enhance bond strength of membrane systems and gives excellent resistance to delamination.

Fire Performance: Provides excellent fire performance with unlimited slope classifications and is non-combustable per UL 790.

Moisture and Mold Resistance: Cement based, highly water durable board, scored a maximum "10" for mold resistance when tested per ASTM D 3273.

JM SECUROCK Glass-Mat Roof Board

Meets the requirements of ASTM C 1177

Handleability: Unmatched mat-to-core tensile bond strength, easy to cut and has reduced facer delamination.

Fire Performance: Provides excellent fire performance, and demonstrates exceptional surface burning characteristics. 5/8" thickness meets the requirements of Type X per ASTM C 1177.

Moisture and Mold Resistance: Fiber glass facer and back with treated core delivers moisture and mildew resistance.

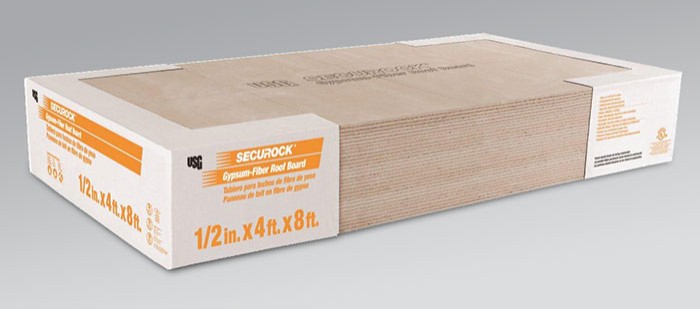

JM SECUROCK Gypsum-Fiber Roof Board

Meets the requirements of ASTM C 1278

Strength: Engineered to provide high wind-uplift performance. Uniform composition providing enhanced bond strength of membrane systems with no risk of facer delamination.

Fire Performance: Provides excellent fire performance, and demonstrates exceptional surface burning characteristics. 5/8" thickness meets the requirements of Type X per ASTM C 1177.

Moisture and Mold Resistance: Integral water-resistant core scored a maximum "10" for mold resistance when tested per ASTM D 3273.

JM Nailboard

Nailboard

Meets the requirements of ASTM C 1289, Type V

(available with 20 or 25 psi ENRGY 3®)

Oriented Strand Board (OSB): Provides a strong nailable surface; always install wood side up. Available wood thickness standard 7 ⁄16" or 5 ⁄8" thick rated "1 OSB". Wood edges are routed 1 ⁄8" to allow for expansion and contraction of the wood.

ENRGY 3: Closed cell polyisocyanurate foam core bonded inline to the wood base on one side and a glass-reinforced facer on the other. Nailboard can also be manufactured off-line using an adhesive between the wood and ENRGY 3.

Vented Nailboard

Polyisocyanurate Insulation meets ASTM C 1289.

(available in 20 or 25 psi ENRGY 3)

Oriented Strand Board (OSB): Provides a strong nailable surface; always install wood side up. Available wood thickness: OSB (7/16" & 5/8"). All wood edges are routed 1/8" on all four sides to allow for expansion and contraction of the wood.

Vent Strips: See pattern on next page. For wood thickness (1", 1.5", or 2").

ENRGY 3: Closed cell Polyisocyanurate foam core bonded inline to glass reinforced facers (See ENRGY 3 data sheet), Vented Nailboard is assembled offline using staples (strip to wood attachment) and adhesives (strip-to-foam attachment).

RetroPlus Roof Board

RetroPlus Roof Board

Meets the requirements of ASTM C 728, Type 3

TopLoc® Coating: Top surface is sealed with this special coating to reduce excessive adhesive absorption in hot-asphalt and cold applied roofing systems, and to provide a strong surface for bonding bituminous membranes.

Expanded Perlite: Provides good dimensional stability, excellent insulation value with stable R-value and superior fire resistance.

Reinforcing Cellulosic Fibers: Consists of recycled newsprint to provide strength to the board as well as high recycled content. JM utilizes third party certification by UL environment to certify the recycled content and contributes to the LEED Materials and Resource (MR) credit 4.

High Density: Provides additional strength and durability over 1/2" Retro-Fit Board with low moisture content and water resistance compared to wood fiber board.

ValuTherm

ValuTherm Roof Insulation

Meets the following requirements:

- ValuTherm / Tapered ValuTherm

- CAN/ULC S704, Type 2, Class 3 (140 kPa)

- ASTM C 1289, Type II, Class 1, Grade 2

- ValuTherm 25 PSI / Tapered ValuTherm 25 PSI

- CAN/ULC S704, Type 3, Class 3 (170 kPa)

- ASTM C 1289, Type II, Class 1, Grade 3

Glass-Reinforced Facers: Provides rigidity and resistance to indentation and crushing, and are compatible with BUR, modified bitumen and single ply membrane systems.

Closed Cell Polyisocyanurate Foam Core: Provides high R-value per inch in built-up, modified bitumen, metal roof and single ply roof systems, and utilizes a zero ozone depletion blowing agent that provides high thermal insulation performance.

ValuTherm CGF - Flat and Tapered

Meets the following requirements:

- ValuTherm CGF / Tapered ValuTherm CGF

- CAN/ULC S704, Type 2, Class 3 (140 kPa)

- ASTM C 1289, Type II, Class 2, Grade 2

- ValuTherm25 PSI CGF /

- Tapered ValuTherm 25 PSI CGF

- CAN/ULC S704, Type 3, Class 3 (170 kPa)

- ASTM C 1289, Type II, Class 2, Grade 3

Inorganic Coated Glass Facers: (With no cellulose) Provide improved resistance to mold growth, as well as a smooth surface that performs well with self-adhering systems, and efficient adhesive application in fully adhered single ply systems.

Closed Cell Polyisocyanurate Foam Core: Provides high R-value per inch in built-up, modified bitumen, metal roof and single ply roof systems, and utilizes an environmentally compliant blowing agent that provides high thermal insulation performance.

Tech Links

Products We Represent

What's New

View AllSep 9, 2024, 2:52 PM

…

Jul 19, 2024, 10:20 AM